- About Us

- Certification

- Why choose RiLong

-

About Us

Provide OEM service for designing ,engineering ,manufacturing plastic and rubber molds&products .

RiLong was established in 1990 in Shenzhen, as an original supplier of high precision plastic injection parts, that were mainly exported to the US and Japan.in 2000 we expanded our facilities and capabilities, covering an area of 11.000 square meters, for manufacturing both plastic molds and injection parts in our house.In 2006 we set up our rubber house in Dongguan with land size of 8000 sqm.

Currently employs 300 skilled and experienced staff members to work in engineering, production, inspection and QC units. With more than 30 professional R&D team, they can always provide our customers with the right 100% in-house manufacturing solutions for developing their products.

Specialist in security cameras,medical , Home alarm system, optical and consumer electronic products etc

Our currently production line has been focusing on security camera housings, optical products,automotive ,medical ,security ,consumer electronic products,specializing in mold design and manufacturing plastic and rubber molds& products, hard&soft plastic over-mold/part,soft plastic& metal pieces over-mold/parts, double injection, LSR/LSR over mold, membrane keypads, as well as the finishing treatments& final assembling, such as screen/pad printing, spraying, laser etching, hot melting, insert molding, packing, assembly etc.

ISO 9001:2015, ISO 14001:2015 ,IATF 1694:2016 and UL-certified Factories

The key factors in helping us to maintain our high quality is the use of following quality systems through all of our business in factory.

1. ISO9001:2015 – Quality Management

2. ISO14001:2015 – Environmental Management

3.IATF16949:2016 – Automotive Industry Quality Management Standard

4. 6S Managing system –SEIRI,SEITON,SEISO,SEIKETSU,SHITSUKE,SECURITY

5. All of the materials are compitable with RoHs and Reach certifications.Trusted by Honeywell, Tyco, Topcon, Canon, Epson, Simenz and More

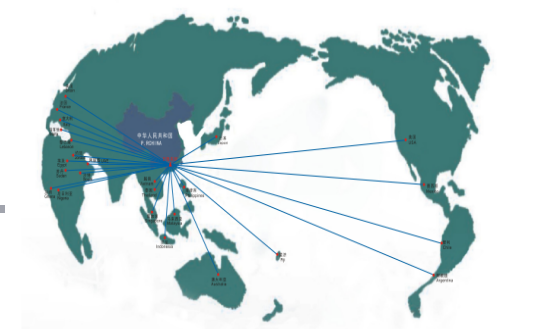

Over the years, we have created more than 4,000 plastic/rubber molds which were exported to the US, Europe and Japan. Simply because we are an ENTERPRISE OF INTEGRITY for providing vertically integrated production in OEM Parts for your one-stop sourcing.

Comprehensive Sales Services

We offer comprehensive sales services, such as weekly updates on your orders, responses to your RFQ and your questions within 24 hours, and timely follow-ups for your project situation.

Main BusinessSince 1990,specialize in Designing, Innovation, Engineering and Manufacturing of OEM plastic, rubber mold and products, over molding, double injection molding, LSR/LSR over mold, membrane keypads.-

Professional Design and Manufacturing for plastic, rubber mould

Professional Design and Manufacturing for plastic, rubber mould -

All of the molding processes can be finished in our house, such as EDM-CNC-Milling-Grinding-Mirror Polishing-Slowness wire cutting

All of the molding processes can be finished in our house, such as EDM-CNC-Milling-Grinding-Mirror Polishing-Slowness wire cutting -

Strong production capabilities for plastic, rubber products in clean room

Strong production capabilities for plastic, rubber products in clean room

-

-

Certification

The key factors in helping us to maintain our high quality is the use of following quality systems through all of our business in factory.

- ISO9001:2015 – Quality Management

- ISO14001:2015 – Environmental Management

- IATF16949:2016 – Automotive Industry Quality Management Standard

- 6S Managing system –SEIRI,SEITON,SEISO,SEIKETSU,SHITSUKE

- All of the materials are compitable with RoHs and Reach certifications

-

Why choose RiLong?Simply because we are an ENTERPRISE OF INTEGRITY for providing vertically integrated production in OEM Parts for your one-stop sourcing.We listen your WORDSWe understand your NEEDSWe work for your AMBITIONSDriven by your desire to achieve more, we have been looking for any break through in today's technologies and cost-effectiveness for your innovative ideas and products.Our vision is to not only deliver products that exceed customer expectations but also to help them reduce costs by working with them in the mold design fields. Our strength is our flexibility and adaptability. We combine our experience with your ideas to bring out products that are one step into the future.

Our cooperated customers, we are not only the supplier, but also we are the best partner.

Our cooperated customers, we are not only the supplier, but also we are the best partner. our market-40% from US, 40% from Europe, 20% from Asia

our market-40% from US, 40% from Europe, 20% from Asia Dedicated and contribution excellent team members

Dedicated and contribution excellent team members